Eco-friendly Barrier Material

- Gas Barrier Solution ‘GB’is mandatory material to establish plastic recycling.

- Plastic is well used in different fields to make our life abundant, but it became a major problem for global environmental issues as it doesn’t decompose naturally. There is active research and development to resolve this issue, and there are two large directions for it: developing biodegradable plastic and establishing plastic resource recycling.

- We are focusing our effort on establishing plastic resource recycling to quickly resolve the issue we faced.

- The keyword for establishing plastic resource recycling is ‘material unification.’ Using multiple materials, such as adding metal to plastic to block oxygen permeation, is what it makes it difficult to recycle.

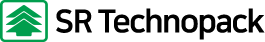

- Gas Barrier Solution ’GB’uses a PVOH-based coating agent that does not use metal material and yet gives an oxygen permeation barrier to a level of metal material with just a thin coating. Such characteristic helps to realize material unification in various field and makes it a mandatory material for establishing resource recycling.

- To expand the applicable area, we are researching and developing a solution that can give quality oxygen permeation barrier and water barrier, and we will be the leading company for establishing resource recycling.

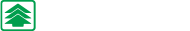

GAS BARRIER SOLUTION

- Our original oxygen barrier coating agent ‘GB’ grants excellent oxygen permeation barrier with just a thin coating.

- This helps cost reduction and material unification of materials; ‘GB is eco-friendly material.

-

- AL BASED IML FILM

-

- Packaging Structure

: OPP·AL·MOPP + PP Cup - ▶ Non Recyclable

- ▶ Non Eco-friendly because of Dry Lami.

- Packaging Structure

-

- GB BASED IML FILM

-

- Packaging Structure

: OPP·AL·MOPP + PP Cup - ▶ Recyclable

- ▶ Eco-friendly(NO Dry Lami!)

- Packaging Structure

- GB’s goal

- Making all products recyclable by putting a stop to metal materials.

-

- Retortable Functional Pouch

-

- Daily Item

-

- Cosmetics

-

- Electronics

-

- Medical Film

GB’s production spectrum

Boiling Grade 'GB-8'

| Base Film | Coating Thickness(㎛) | Film Thickness(㎛) | OTR(cc/㎡·day) | Wrinkle Resistance | Splitting Resistance(gf/mm) | Water Resistance |

|---|---|---|---|---|---|---|

| Nylon | 1.2 ± 0.2 | 25 | < 0.3 | Good | 450 ± 40 | 90℃ Boiling 2 Hours ± 20min |

| OPP | 1.2 ± 0.2 | 20 - 100 | < 0.5 | Good | 400 ± 30 | |

| PET | 1.2 ± 0.2 | 12 < | < 0.3 | - | 500 ± 40 | |

| CPP | 1.2 ± 0.2 | 30 < | < 0.3 | Good | 800 ± 40 | |

| MOPE | 1.2 ± 0.2 | 25 < | < 0.3 | Good | 600 ± 40 |

Retort Grade 'GB-9'

| Base Film | Coating Thickness(㎛) | Film Thickness(㎛) | OTR(cc/㎡·day) | Wrinkle Resistance | Splitting Resistance(gf/mm) | Water Resistance |

|---|---|---|---|---|---|---|

| OPP | 1.2 ± 0.2 | 20 - 100 | < 0.5 | Good | 400 ± 30 | 121℃ Retort 1 Hour |

| PET | 1.2 ± 0.2 | 12 < | < 0.3 | - | 500 ± 40 | |

| CPR | 1.2 ± 0.2 | 60 < | < 0.3 | Good | 800 ± 40 |